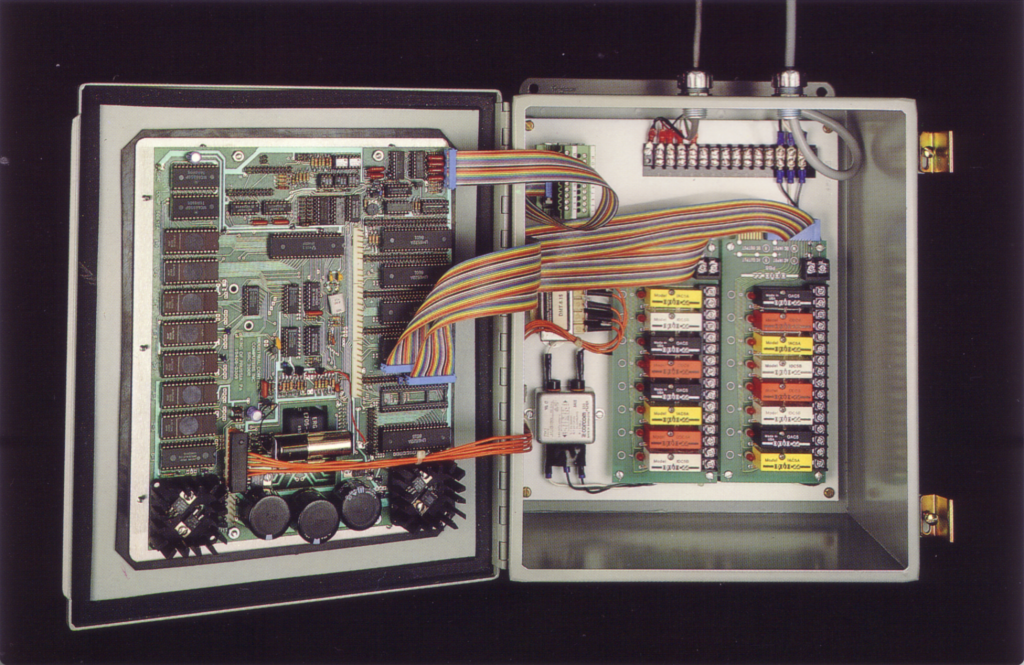

SBC-200B Industrial Single Board Microcomputer

The SBC-200B Industrial Single Board Microcomputer is a dedicated computer controller for industrial applications available with a NEMA 12 alpha numeric display and keypad, protected by a vertically mountable hardened case.

| The SBC-200B is a third generation quality microcomputer that reflects the experience gained from thousands of systems installed in a variety of industrial applications worldwide over the last century. It has been uniquely designed to provide in one cost effective panel mounting industrial package both the high speed control and computational power of a microcomputer and a NEMA 12 operator interface having a highly legible message display and data entry keypad. |

SBC-200B Features

The 2 megahertz clock speed of the microprocessor provides speed of response much faster than that of a Programmable Controller, permitting the SBC-200B to count at speeds of up to 10 KHZ, and turning an output on or off within less than a millisecond after a set point is reached. Time of outputs can be controlled with resolutions and accuracies of a millisecond or less if needed, and very high-speed analog signals can be read and controlled with precision. The SBC-200B differs from a personal computer in that it has a two line, 20 character alpha‑numeric vacuum fluorescent display in place of a monitor, and a for keeping track of variable function keys instead of a keyboard. The software is burned into EPROMS, rather than stored on floppy disks, and the construction is intended for use in manufacturing environments.

Input/Out Capabilities

The display, keypad, three LED light bars and a pair of machine start/stop pushbuttons are mounted on a separate operator interface board which can be plugged into the front of the SBC‑200B, or remotely mounted. Mounted behind a cutout in the customer’s panel, the operator interface displays the setup questions for the machine or process, to which the operator responds by entering instructions on the keypad. The instructions for a number of different machine setups can be stored in the computer’s memory, then easily retrieved via the operator interface when a previously used setup is to be repeated.

Up to 80 inputs and outputs, AC or DC, can be monitored and controlled by the SBC‑200B, frequently requiring less I/0 than a programmable controller, since the operator interface can eliminate pushbuttons, lights and selector switches used with PC’s.

The two built-in serial ports facilitate communications with a host computer, printer, graphics monitor, or network. Optional A/D converters can monitor up to 8 analog inputs at high speeds, with resolutions up to 1 part in 32,000. A real time clock is available for use with production reports.

Additional Information

Explore the core capabilities of our device.

Operator Interface

A standard overlay is offered for the operator interface panel, with commonly used labels for the function keys. Custom overlays can be used on proprietary systems to include your logo and key labeling to suit your requirements.

Application Software

The application software is normally written in high level language, such as “C”, using an IBM or compatible microcomputer, then compiled and burned into EPROMS for installation in the SBC-200B. Battery backed 8 K RAM chips are used to handle 5 by 5 array keypad with numeric and special dynamic memory data. The software can be written by us, by you, or by a third party; we offer a library of commonly used subroutines in the “C” language for those who wish to write and support their own programs.

Cost Savings

The SBC-200B is normally less costly than comparable systems with bus based boards assembled in card cages, and also less than most programmable controllers having somewhat comparable capabilities. Software development costs usually are higher with a microprocessor system than with a PC, but this maybe offset by additional capabilities, or by amortizing the expense over a number of systems with reduced hardware costs.